The Brits are doing their best to recycle. They have a system called that uses something called a Packaging Recovery Note (PRN). Basically the government sets a target goal for recycling in various industries. Companies can either meet these goals, or purchase Package Recovery Notes, much like a cap and trade system but for recycling. Companies that do a very good job of recycling can sell the extra notes for a profit.

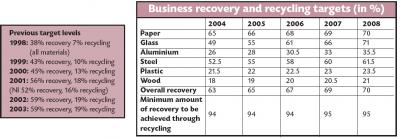

The table above shows what each industry needs to meet for the next couple of years. To learn more about the PRN system read this (pdf).

The good thing about this is it encourages companies to recycle, but it also encourages them to make less packaging. Less packaging means less to recycle, or less PRN’s to buy.

Corus Steel Packaging Recycling, has launched its 2006 annual PRN report (pdf), highlighting the significant achievements that have been made thanks to Corus’ investment of PRNs (Packaging Recovery Notes). Steel packaging recycling rates in the UK were at record levels last year at 57.3 percent.

This year’s report ‘Leading in Recycling’ demonstrates to the packaging industry how Corus’ PRN funds have been invested to help boost steel packaging recycling rates to a record level of 57.3%.

Packaging chain companies are obliged to purchase PRNs as evidence that their legal responsibility to recover and recycle quantified tonnages of packaging has been fulfilled. PRNs are sold by accredited recycling operators, either to an obligated company or to a compliance system acting on their behalf.

In 2006, Corus invested PRN funds in a number of areas to facilitate and enhance the collection and recovery of steel packaging. Examples of some of the achievements detailed in the report include:

1. More than 32 projects and 53 local authorities benefited from Corus’ investment of PRN funding in 2006

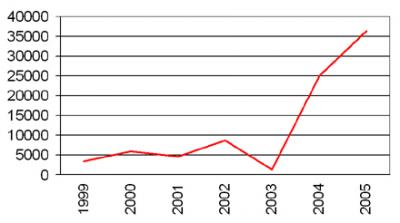

2. CanRoute celebrated its seventh anniversary, diverting more than 145,000 tonnes of domestic steel packaging from landfill since it was established in 1999

3. 47,000 tonnes of steel were recovered via CanRoute in 2006 – a 31% increase on 2005

4. PRN funds were used to undertake trials and research at Corus’ Port Talbot plant with a view to using more can scrap in the BOS (Basic Oxygen Steelmaking) process, meaning that more scrap could be collected for recycling purposes

Corus’ PRN report also looks at what the company hopes to achieve in 2007 as David Williams, manager of Corus Steel Packaging Recycling, explains:

With the UK’s steel packaging recycling rate already surpassing the 2008 target of 54% set by the UK Government two years early, the challenge now is to continue this momentum. Our priorities are to maintain record recycling levels for steel, and to ensure that as many people as possible recognize that steel is a safe, sustainable and successful packaging medium. The strategic application of PRN funds will help to ensure that our previous achievements in this field continue, demonstrating to our customers and the packaging industry as a whole, our commitment to investing in the future of steel packaging recycling.

Installing systems like this in the USA would pressure companies to take responsibility for their grossly over packaged goods, increase the rate of recycling, and develop new industry and jobs. Not to mention the large reduction in CO2 emissions (recycling uses less energy than creating something again from scratch).

Here is a video of how the steal can recycling works at Corus.