From time to time The Sietch likes to highlight interesting companies that are shaking things up in the sustainable products world. I had the good fortune to check out the booth of Advanced Composting Systems at a recent green building conference. Later I exchanged emails with James Conner, the communications director for ACS, which manufactures the Phoenix Composting Toilet system.

The capacity of the Phoenix system depends on the size of the tank, the temperature of the compost pile, and the frequency and quality of maintenance. Warm tanks have a higher capacity than cold tanks. Our capacity ratings assume a minimum tank room temperature of 65F (18 C), our minimum recommended temperature. Below 55F (13 C), composting is very slow. The R-199 cabin model can be used continuously by two persons. The R-200 accommodates four full-time users. The R-201 accommodates eight full-time users. Model R-200 can be upgraded by adding a midsection. Model R-199 can be upgraded by adding a midsection and/or a 200 level top. Copyright 2007, Advanced Composting Systems, all rights reserved.

The Phoenix composting toilet factory and company headquarters is in Whitefish, Montana, in the northwestern corner of the state, not far from Glacier National Park. The founder and president (and factotum) of ACS is Glenn Nelson. ACS dates back to the early 1970s, getting its start manufacturing composting toilets for another manufacturer. In the mid-1980s, Glenn, who has a graduate degree in physics, designed a new and improved composting toilet, which he named the Phoenix, and began producing it. Phoenix is a family run business (like another composting toilet maker I met, this sort of thing must run in the family) both of his sons, Ried and Brent, work for ACS, with Ried working as the vice president for production and finance. In addition to a seasoned crew of carpenters, welders, and fabricators of small parts, the staff includes an electrical engineer and technical editor.

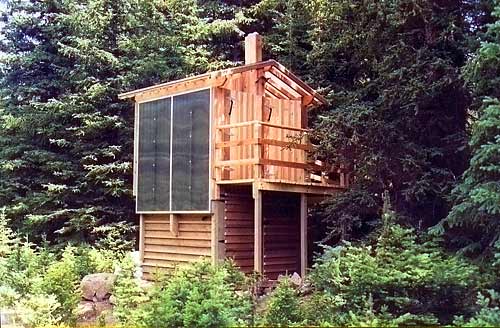

Sunergy Systems, LTD, of Cremona, Alberta, designed and built this Phoenix equipped, finely crafted building for the West Vancouver Yacht Club. Constructed of cedar, the building features a waterproof Lexan roof that lets plenty of light into the building. Photovoltaic panels affixed to the wall drive the Phoenix's low wattage fan and pumps. Sunergy is widely admired for its ability to combine traditional and modern materials to produce aesthetically pleasing and resource friendly facilities. Copyright 2007, Advanced Composting Systems, all rights reserved.

At the factory they manufacture three sizes of composting toilets for residential and public facility installation. They also design, manufacture, and install, prefabricated, solar powered, buildings for public facilities. With a specialty in self-contained buildings for remote locations, such as in the Grand Canyon and along the Deschutes River (central Oregon). They seem to have a knack for building composting toilets in some of the most interesting places on the earth. Keeping these places clean, while allowing a bit of comfort for the visiting public.

Hawaii Volcanoes National Park occupies 320,000+ acres on the Big Island of Hawaii and encompasses ecosystems from sea level to almost 14,000 feet. One of the most spectacular, remote, and popular hiking destinations is Halape, a landscape of cold lava, little white sand beaches, sea turtle nesting grounds, and tropical palms swaying in the sea winds. Working with NPS personnel, ACS designed and prefabricated this rustic looking building with modern features that was air-lifted to the building site and reassembled by an ACS led crew. Black volcanic rock now conceals the white area on the building to the left. Copyright 2007, Advanced Composting Systems, all rights reserved.

When I asked them what ecological benefits their products have, they replied:

“The Phoenix is a dry composting toilet — human waste is the only liquid input. This makes the system ideal for situations in which water is scarce — for example, a desert — or the water table is too high — for example, a trail head next to a marsh. If necessary, we can configure the system so that there is no on-site discharge of treated wastes. That reduces the impacts on sensitive sites where visitors are allowed.”

Located along the Crooked River in Central Oregon, Smith Rock is popular with rock climbers. Two Phoenix composting toilet systems and evaporators provide an odorless, zero-discharge, comfort station for the park's many guests. A photovoltaic array built into the roof generates power. Prefabricated in ACS's climate controlled factory in Whitefish, MT, the building's sections were hauled to the site on ATVs and reassembled by ACS's expert crew. This greatly reduced construction impacts. A fierce wildfire stormed through the tinder-dry park in 1996, but the cement-sided Phoenix facility escaped unscathed. Copyright 2007, Advanced Composting Systems, all rights reserved.

While browsing around their site, I found to my surprise that they have collected some famous mentions (pdf) of composting toilet literature throughout the ages. Including this interesting passage from Victor Hugo’s Les Miserables. These people are clearly passionate about composting toilets!

After long experimentation, science now knows that the most fertilizing and the most effective of manures is that of man. The Chinese, we must say to our shame, knew it before us. No Chinese peasant, Eckerberg tells us, goes to the city without carrying back, at the two ends of his bamboo pole, two buckets full of what we call filth. Thanks to human fertilizer, the earth in China is still as young as in the days of Abraham. Chinese wheat yields a hundred and twenty-fold.

There is no guano comparable in fertility to the detritus of a capital. A great city is the most powerful of dung producers. To employ the city to enrich the plain would be a sure success. If our gold is manure, on the other, our manure is gold. What is done with this gold, manure? It is swept into the abyss.

When asked about the cost for these jobs they reassured me that:

“The cost of a composting toilet tends to be equal to or less than the cost of competing, more traditional systems, in situations in which a composting toilet is an advantage. Technical support by telephone and email is part of the package, not a gouge the customer add-on.”

Nice to know if my crapper breaks that there will be someone ready to help me out. If you are interested in getting your own Phoenix Composting toilet you can contact them at their website.

by email: phoenix@compostingtoilet.com

by phone: 406-862-3854 = land line for ACS in Montana

I’m really interested in composting toilets for the hexayurt project (infrastructure for refugees etc.)

But I have a question: would these still be $5000 each if they were being manufactured in 100,000 quantities? Is the price an economies of scale thing or is there some really hard engineering problem in there?

Hello Vinay: I am really not sure. I am sure they would be more than happy to talk to you about it (check out the contact info about the bottom of the post). They seem like pretty nice people, so you know its worth a shot.

There’s not much to a composting toilet, in terms of materials or complex design. Once they’re mass produced in China and shipped out in flat packs (like the BiPu emergency septic tank) they should be very cheap. Can’t see why not.

That attempt at an HTML link doesn’t seem to work – so try http://en.wikipedia.org/wiki/Bipu

This seems like it would be a great system for outdoor toilets… parks, camps, etc. And definitely a lower cost and lower maintenance option than a septic system.