Intro on Eco-friendliness of PVC Roofing:

It is not a secret that PVC, or polyvinyl chloride will never be good enough for the hard core environmentalists, and it is not my goal to change their view of PVC for the better. Instead, I would like to demonstrate how the use of PVC in residential and commercial roofing is good not only for homes and commercial buildings along with their occupants, but also for the environment.

Original Post Background and Update Details:

This post was originally, published on January 19th, 2009, and this is a refresh and an update of the earlier post. Please note that although this post has been polished a bit, all the content along with any claims, arguments, and points of view that post authors have expressed in the previous post have remained unchanged. Further, all the comments that this “controversial” post has received are still relevant today, and can be read below the post.

Here is what the Big shots in the likes of Green Peace have to say:

Before we dive into the environmental benefits of PVCs roofs, let’s hear what prominent, PVC-opposed minds have to say, and see if their argument really holds much ground…

Greenpeace reference to PVC as Poison Plastic – although somewhat biased and subjective, this view represents a general view of the green community towards PVC. My goal is not to prove that PVC is good or bad, but rather, to demonstrate that in a real world, PVC roofing has a lot more positive effects on the environment vs. other far more prominent flat and low slopped roofing systems.

In Lieu of Prologue:

In the fall of 2008, I was taking a Solar Training class at RI Community College and one of my classmates had a Bio-Diesel conversion done on his Ford F-250. At the time, He needed a bed-cover for his truck, so I offered him to use a spare piece of PVC roofing membrane that I had left over from a job we previously completed. From a practical perspective, a 6 by 6 feet piece of grey IB PVC membrane would work perfectly as a truck bed cover, so we agreed that I’d bring it to our next class, and that I would help him install it.

Before we actually had a chance to get it done, Mark has called me up saying that PVC is extremely toxic, bad for the environment, and that his wife was greatly opposed to the idea of him using PVC membrane to protect the bed liner in his truck!

Needless to say, I was shocked upon hearing this! For as long as I have been in the roofing business, installing cool flat roofs and green metal roofing systems, I have always held a view that PVC roofing is as Eco-friendly as it ever gets, compared to the rest of roofing products used in the industry. The reaction of Mark’s wife has prompted me to really go ahead, research, and examine environmental factors concerning PVC roofing. This article is a summary of my analysis of the impact that PVC roofing has on the environment, and I am going to do my best to objectively show, and compare positives and negatives of PVC roofing.:

Note: For comparison purposes, I am going to use a PVC flat roofing membrane produced by IB roof systems based out of Eugine, Oregon. Bear in mind that IB uses their own, proprietary formulation which they also call CPA, or “co-polymer alloy”, which is kept as a trade secret.

What is PVC?

In simple words, PVC is one of the most-commonly used type of plastics in the world. There are many reasons why PVC is so popular among all the other plastics. It’s due to the fact that PVC is generally cheaper than many other plastics, and thanks to its incredible durability. Unlike many other plastics that are essentially made of 100% fossil fuels, PVC is made of only about 50% fossil fuel, namely natural gas or methane. The second half is chlorine, a gas that is a main component of rock-salt.

Chemical Composition of PVC:

Vinyl is essentially derived from two simple ingredients: fossil fuel and salt. Petroleum, or natural gas is processed to make ethylene, and salt is subjected to electrolysis to separate out the natural element chlorine. Ethylene and chlorine are combined to produce ethylene dichloride (EDC), which is further processed into a gas called vinyl chloride monomer (VCM). In the next step, known as polymerization, the VCM molecule forms chains, converting the gas into a fine, white powder called vinyl resin, which becomes the basis for the final process, compounding. In compounding, vinyl resin may be blended with additives such as plasticizers for flexibility, stabilizers for durability and pigments for color.

Through various plastics processing operations, manufacturers are able to offer versatile products with customized performance characteristics.

What is PVC Roofing?

PVC roof is a single-ply membrane that consist of two plies or layers of PVC material with a polyester reinforcement scrim between the layers. Top ply has special additives to make the membrane UV stable and prevent curing, and plasticizers to make it flexible, and pigments for color. IB also uses a layer of acrylic coating to make their roof more reflective, and to help repel dirt and dust. Bottom ply is a black PVC with plasticizers for flexibility and usually no other additives or fillers.

During the installation, PVC roofing membrane sheets are connected together by using hot-air welding (fusion welding) of seams, which creates a permanent physical bond between two separate sheets of roofing membrane. This hot-air welding process is what makes PVC roofing such a great roofing product – it can remain water-tight and pliable for decades after the originally installation.

Negative side of PVC: Greenpeace, toxic waste and dioxins, plasticizers, etc.

According to Greenpeace, during the PVC production, use, disposal and/or accidental burning, numerous dangerous and toxic chemicals are produced and/or emitted. Among them Dioxins, some forms of which are know as human carcinogen and can cause or accelerate cancer. Also, in order to make PVC flexible, a plasticizer called phthalate is added. Greenpeace claims that Phthalate is a major health risk, and can be one of the causes of asthma.

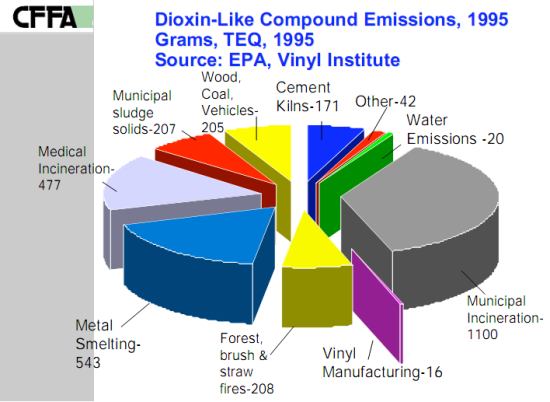

Dioxins: According to a study by EPA and Vinyl Institute, PVC production contributes about 0.5 % of all Dioxin emission, compared with municipal and medical incineration and metal smelting making up more than 2/3 of all dioxin emissions.

Also, bear in mind that numerous studies by EPA, FDA and other government agencies in the US, Europe and elsewhere around the world show that PVC is actually very safe for human use, during production, lifespan and recycling.

Did you know that PVC is widely used in medical and health care industry. for instance, Intro venomous (IV) liquid/blood bags and tubing are made from PVC, and are FDA approved?

Claims about PVC recycling are also ludicrous for the most part, as many PVC products are so durable, they are still in service, decades after they were produced, and will serve for many more years.

Of course there are negative sides to PVC, but instead of making this article seem like it is in defense of PVC, I would like to share arguments and facts form both sides of the isle, so you can make a more educated decision in regards to PVC products. Thus, the purpose of this article is to demonstrate the environmental benefits of PVC roofing as compared to other roofing products.

PVC reference information:

Greenpeace: PVC – Poison Plastic

CFFA: VinylRoofs.org

PVC Roofs – a Cool and Sustainable roofing choice.

Let me first establish a fact that in a flat roofing market, there is no 100% green option. The only exception would be low-slope metal roofing systems used on space metal buildings, but these cannot be use for regular flat roofs, as they will never be able to withstand ponding water.

Further, keep in mind that Cool metal roofing for pitched roofs, both residential and commercial, is a true green choice, as metals roofs that are almost always made from a metal containing a significant proportion of recycled content, can easily last in excess of 50 years, and are completely recyclable at the end of their service life.

However, for the purpose of this article, I will concentrate on flat roofs.

All flat roofing materials in use today, in on form or another, are based on fossil fuels, namely petroleum. Despite a lack of real green flat roofing options, more than half of all roofs in the world are flat, and it just so happens that no one wants their roof to leaks. Let’s review prominent, modern flat roofing choices in a greater detail:

- EPDM – Black rubber: stands for ethylene propylene diene M-class, where ethylene and propylene are carbohydrate byproducts of oil refining, and make up about 97% of EPDM roofing membrane. EPDM is the most common type of flat roofing installed today.

- Asphalt rolled roofs and asphalt shingles roofing: These really require no explanation, but based on heavy oil or bitumen, asphalt roofing consists of 90% pure extra-heavy oil. A fiberglass mat base is saturated with asphalt, and is coated with crushed stone to provide protection from UV. This is your typical asphalt roofing.

- Built-up tar and gravel roofing: Contains 3 to 5 layers of heavy paper saturated in, once again, bitumen, put together with hot tar, or other methods. Covered with gravel. Usually there is a hot-asphalt kettle emitting poisonous bitumen fumes, present at the job-site for the entire neighborhood to enjoy.

- Modified bitumen – APP and SBS: Both are pure bitumen compounds modified with either plastics (APP), or rubber compound (SBS), and reinforced with either fiberglass mats, or a polyester scrim. These rolled roofing is very thick, with ¼ inch thickness of each ply. This roof is usually installed in 2-3 ply assembly by either using a torch with an open flame to melt asphalt, which by design sticks to the substrate, or hot-mopped with liquid hot tar or asphalts, or cold-applied.

- TPO Thermoplastic Olefin: A so-called “PVC killer” as many roofing consultants and analysts refer to it, TPO is a cool roofing alternative to PVC roofing, which was designed to be cheaper to produce than PVC, yet to it was supposed to offer the same cool roofing advantages in combination with a hot-air welding of seams installation process – This is what makes PVC such an outstanding roofing product.

PVC vs. TPO Roofs in the US:

Unfortunately, first generation of the US-made TPO roofs has failed to achieve the proven reliability of PVC, and first batches of TPO have failed after just 8-11 years of service, with isolated cases failing much faster. Read our in-depth review and comparison of PVC and TPO roofing membranes.

In the period between 1999 and 2002, all major American TPO manufacturers pulled their products “off the shelves”, and went through a major reformulation to eliminate material and weld failures associated with the first generation of the US-made TPO products. Today, most TPO roofs installed represent the 2nd generation. Still, not even the manufacturers themselves know how long they will last. Most of the 1st generation, failed TPO roofs is now quietly and peacefully contaminating our landfills, as TPO is not suitable for recycling.

Chemically, TPO is once again, completely based on fossil fuels – propylene and olefin are both carbohydrates extracted from oil. TPO also uses cheap plastic fillers as its bottom ply to achieve a minimum required thickness of ASTM standard for single ply roofing. These cheap fillers are one of the major causes of TPO failures.

All of the above flat roofing products end up in our landfills after they reach the end of their service life. Non of them are suitable for recycling. It also takes about 400 years for asphalt to naturally degrade. For modified roofing such as EPDM, APP, SBS and TPO, it will take a much longer period to degrade, and bear in mind that there are billions of square feet of Asphalt, Modified Bitumen, TPO, Tar & Gravel roofs coming to the end of their life cycle each year, in US alone. 99% of all these roofs will end up in landfills.

Cool Roofs vs. Black surface roofs.

For an average 2000 sq. ft. flat roof on a house in Boston, MA, installation of a cool roof will help reduce annual electrical costs by $160. This equals to almost 1000 kWh of electricity saved. In California, installing a cool roof on the same house would save $440 per year, or about 1500 kWh of electricity. Above calculations account for winter heat loss difference between black and cool white roofs. Also, despite the claims of black roof manufacturers, Cool roofs save a lot more money and energy as compared to black roofing products. Here is why:

- In the winter days are almost twice as short as in the summer and sun sits very low to the horizon, so most of the passive solar heat transfer occurs through the windows – not roof.

- In the winter, flat roofs are usually covered with snow for long periods of time, so roof color makes no difference in such situation. Also, there are more cloudy days in the winter, which further reduces potential heat absorption of a black roof in the winter.

It is estimated that cool roofs save American economy more than $3 billion annually. Now imagine if all roofs in US would suddenly become cool?

PVC – the only true green and sustainable flat roofing choice.

I say this knowing that Greenpeace and many environmentalists consider PVC a poison and that it has great opposition in the green community. So why do I call PVC a green and sustainable roofing product?

There are billions of square feet of flat roofing that has to be water tight. You have only so many alternatives, and PVC stands aside from the rest of the crowd. All other flat roofing products:

- Require more fossil fuels as their main chemical components.

- Use more energy in the process of extraction and manufacturing.

- Are not recyclable, which means that millions of tones of waste roofing will go to our land fills each year.

- Have black surface which attracts heat and transfers it inside home or building. This in return requires more energy to keep the inside temperature comfortable (this excludes TPO membranes as discussed above).

- Have a life span that is only about a ½ of the PVC life span. This means that while 1 PVC roof is installed and serves for 30 years, saves thousands of kWh of electricity during its life-cycle, after which it gets recycled – two black surface roofs are installed, removed and dumped to the land fill.

Despite all the criticism of PVC from environmentalists, fierce competition from other, cheaper flat roofing products such as EPDM roofs, and now TPO membranes, PVC roofs continue to dominate commercial roofing market in Europe. In fact, PVC roofs hold almost 62% of Flat Roofing market share in Europe, and have gained wide acceptance and popularity in the US, where some 15 years ago, industry analysts said that PVC roofing membranes are about to disappear. Not only that, IB Roof Systems has been growing their business by at least 15-20% each year in the last 15 years in the U.S. 2007 was their best year to date – product sales grew by over 45%. In addition to just rapid expansion of their core roofing lines, IB added their SolarWise product, which integrates time-proven PVC roof with Uni-Solar thin-film photovoltaic laminates to create a true, roof integrate solar PV system. There are other PVC manufacturers out there that also use their very popular PVC roof with UniSolar PV laminates to achieve a great combination of cool, energy saving roof and electricity generating Solar Panels.

IB and other PVC membrane is also perfect for Green roofs, as they are environmentally safe and remains watertight for decades. This eliminates a need for removal of the roof vegetation, and soil when the aging roof begins to leak.

Hardcore environmentalists and PVC roofs – instead of conclusion:

So before you bash PVC roofing as being poisonous, toxic, bad for environment, etc. – answer a question: “which (flat) roof would you choose for your own home?”

Would you pick an all petroleum based roof that would end up in a dump in 10-15 years, and would keep on polluting, or would you opt out for a sustainable roofing membrane that keeps your building cooler, and greatly reduces the amounts of CO2 and other green house gas emissions; a roofing system that saves money and provides long lasting reliable protection for your home. Forgetting about those annoying roof leaks and expensive repairs, How is that for a peace of mind? Not to mention, that at the end of service life, which is expected to be at least 30 years (conventional flat roofs often fail in the first 10-15 years requiring complete replacement) PVC flat roofing membrane by IB roofs is 100% recyclable.

I welcome your opinions, comments and other input – please let me know what you think.

References:

Author Bio:

This editorial was written by Leo Biyevetskiy of Cool Flat Roof in collaboration with Aleksandr Biyevetskiy – Follow Alex on Google Plus here:

Follow Aleksandr Biyevetskiy on Google Plus